Advanced Control Strategies

Product Quality

Enable Real-Time Release Testing (RTRT) and respond to process changes instantly. No need to wait for offline lab results

and Variability

Enable continuous processes with steady-state performance and adaptive process optimization. Increase throughput, lower operating cost, and accelerate scalability

Advanced Knowledge Management and Process Control for Regulated Industries

As High-tech industries - including pharmaceuticals, food, biotech and specialty chemicals - move toward smarter, more responsive manufacturing, advanced control strategies are becoming essential. These approaches go beyond basic automation; they rely on real-time data, predictive models, and integrated systems to maintain quality, reduce variability, and meet strict compliance standards. Yet implementing them is far from straightforward: data flows from multiple sources, instrumentation often operates in isolation, and regulatory oversight demands full transparency.

Streamlined Process Control and Compliance

SciY addresses these challenges with synTQ—a software suite purpose-built to streamline knowledge management and process control. synTQ enables organizations to implement intelligent, data-driven strategies through a combination of smart control strategies such as Process Analytical Technology (PAT), Quality by Design (QbD), model-based control, and real-time release testing. It integrates with a wide range of equipment and instrumentation, enabling synchronized, adaptive control across both development and manufacturing environments.

synTQ is developed for, and running in, validated, GxP environments around the globe . It helps organizations stay audit-ready and compliant according to the principles of data integrity, ALCOA+, and 21 CFR Part 11. synTQ unifies real-time monitoring, predictive modeling, and automated decision-making within a single, scalable platform.

Driving Better Outcomes through Real-Time Analytics and Full-Scale Digitalization

Most importantly, synTQ helps reduce process variability and improve product quality. Through continuous analytics and automated responses, it enables early detection of deviations and proactive control—minimizing batch failures, accelerating release timelines, and strengthening overall manufacturing performance.

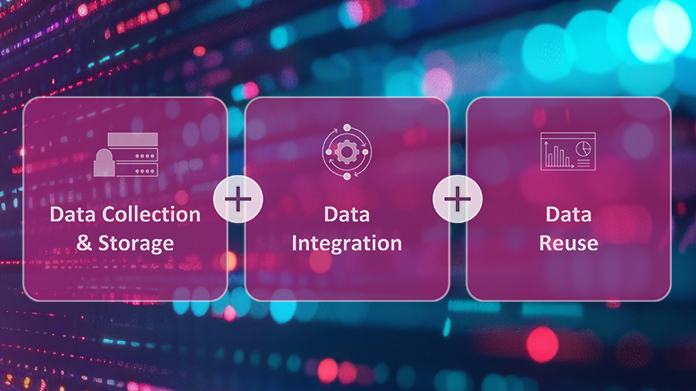

Beyond individual process gains, synTQ supports full-scale digitalization by integrating seamlessly with MES, LIMS, Data Platforms and other enterprise systems. This end-to-end connectivity breaks down data silos, ensures traceability, and enables a unified control strategy; creating a foundation for AI-driven innovation, continuous improvement, and long-term compliance in line with Pharma 4.0 maturity goals.

Read more on Why Choose synTQ for Advanced Control Strategies?

Curious about our products or services? Let us provide you with the answers you need. Contact us today and discover how we can cater to your needs effectively.