Next Generation LIMS

with Regulations

Streamline workflows, automate routine tasks, and optimize processes to maximize efficiency, improve quality

The Ultimate LIMS Solutions for Your Laboratory Needs

Laboratories face recurring frustrations with traditional Laboratory Information Management System (LIMS): clunky interfaces that slow workflows, painful integrations that leave instruments and ELNs in silos, costly customizations that break with every upgrade, and the ongoing headache of migrating or preserving legacy data. The result? Scientists fall back on spreadsheets, critical information gets lost across disconnected systems, and compliance risks multiply.

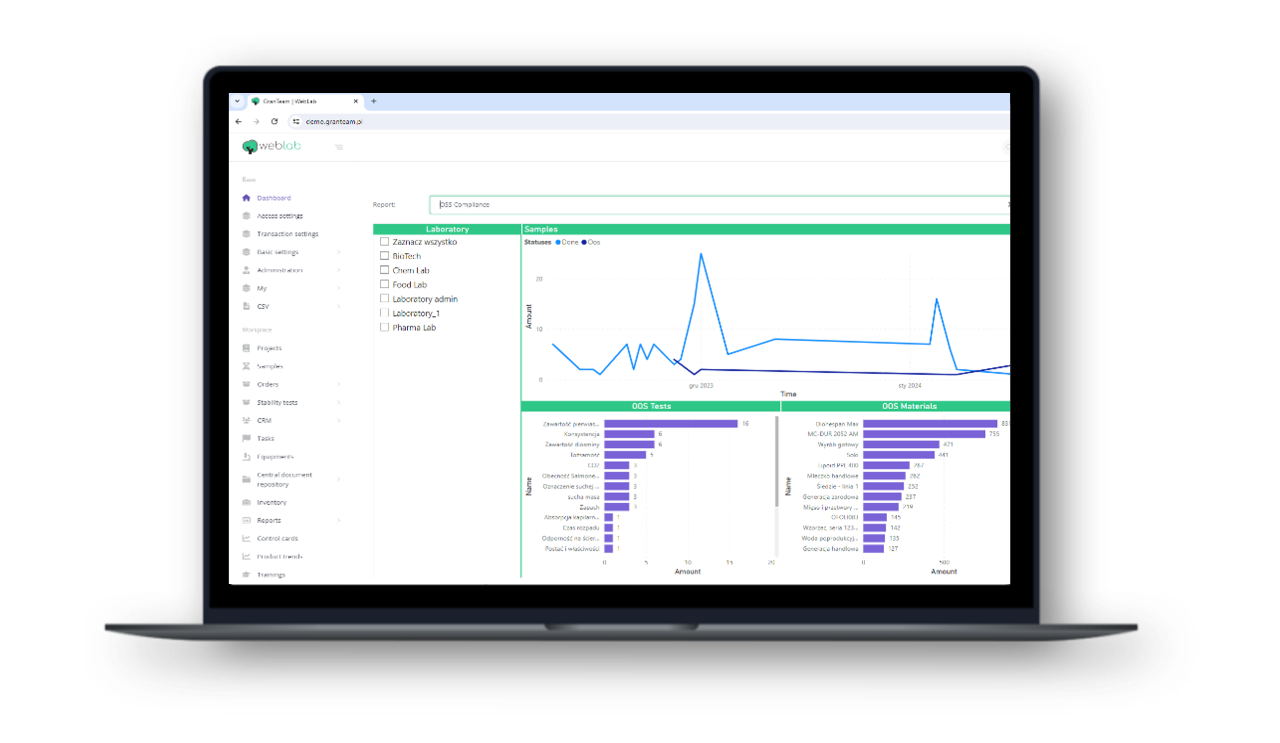

SciY addresses these challenges directly. WebLab, our modern cloud-based LIMS, is built for usability and rapid adoption. It offers intuitive workflows, low-code configuration, and seamless integration with instruments and other lab systems. When no-code configuration options are not sufficient, additional modules can be added to meet evolving operational and business needs. Compliance is built in from day one with audit trails, e-signatures, and regulatory templates ensuring readiness for industry standards and regulations.

For laboratories with complex data landscapes, SciY provides an advanced data platform, ZONTAL, that consolidates and standardizes information across LIMS, ELNs, and other systems. This eliminates manual data assimilation, simplifies migrations, and ensures accuracy. ZONTAL preserves and unifies legacy records, delivering a single, reliable source of truth that’s integration-ready for analytics and AI.

Get Your Personalized ROI Analysis

Still running your lab on spreadsheets or manual workflows? You could be losing valuable time and profit every week.

Request a free ROI analysis to discover:

- Where your current processes are wasting time and resources

- The ROI your lab could achieve by going digital

- How leading labs boost throughput, compliance, and reporting with LIMS

Fill out the form, and our experts will reach out and create a personalized analysis tailored to your lab’s needs.