Modernizing Method Transfer: How Digital Transformation is Solving an Old Problem in Analytical Labs

1. Persistent Challenges in Analytical Method Transfer

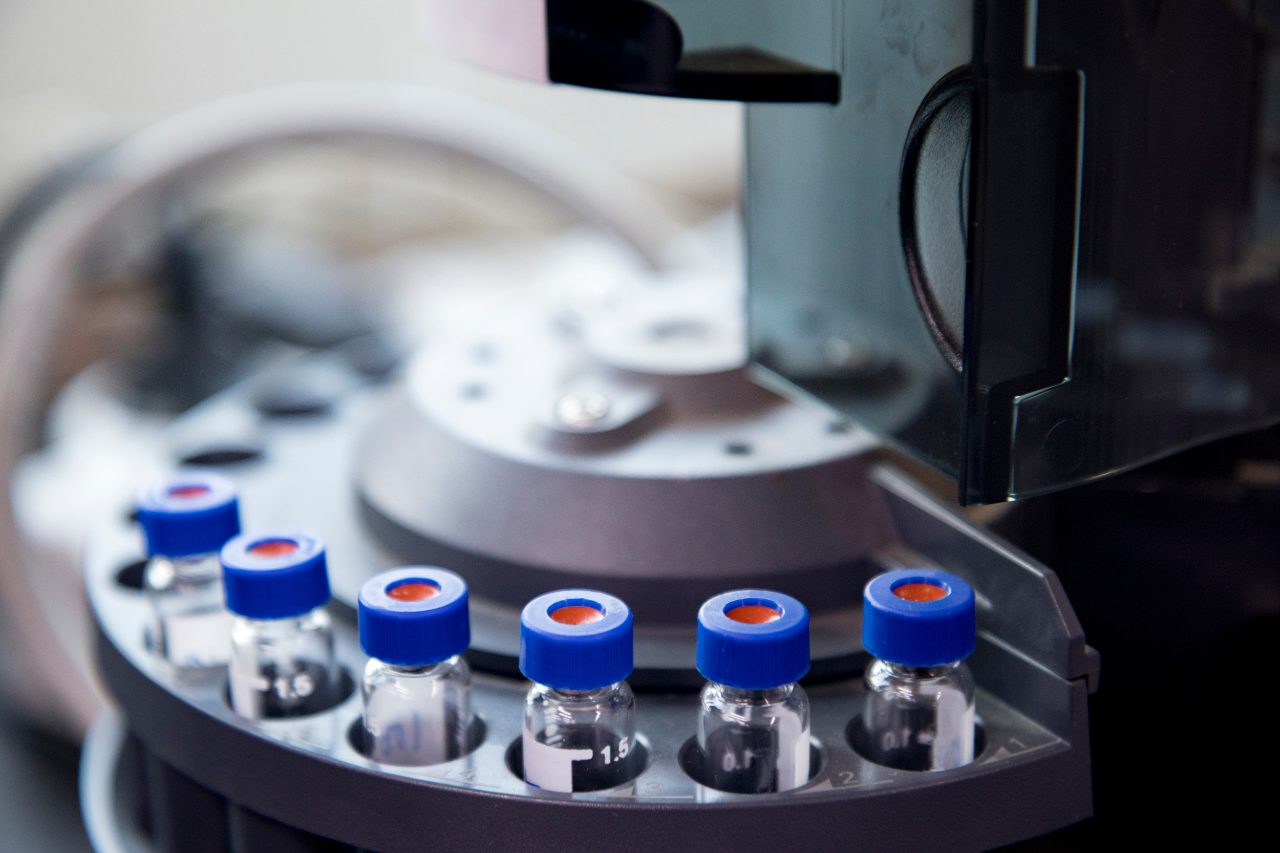

In pharmaceutical organizations, the development and validation of chromatographic methods is a routine but resource-intensive task. Once a method is optimized and performs reliably, there’s a natural expectation that it will remain effective long term. Yet in practice, the landscape is far more dynamic. Instruments are upgraded, systems evolve, and methods often need to be shared—whether across internal labs and global sites or with external partners like CROs, CMOs, and CDMOs. To maintain efficiency and consistency, these methods must transfer seamlessly between different teams, platforms, and locations. Unfortunately, that’s rarely the case.

Method transfer remains a highly manual and fragmented process. Scientists still rely on emails, PDFs, and even printed documents to communicate essential method parameters. Receiving labs must then re-enter this information by hand into their own systems—a time-consuming process prone to human error, misinterpretation, and mismatched terminology.

This challenge is compounded by variability between different chromatography systems and software. An HPLC method developed on one platform may require tweaks when implemented on another due to differences in purge volumes, injection cycles, dwell times, or even how certain parameters are defined. Even seemingly minor variations can drastically affect retention times, peak shapes, and resolution—putting method robustness and reproducibility at risk.

The result? Time lost troubleshooting. Inconsistent results. Projects are delayed. And regulatory submissions become harder to defend.

Are you familiar with this? Hang on, you might not know it, but experts have been working on solving this problem.

2. Why the Industry Needs a New Approach

For years, labs have accepted this inefficiency as the status quo. But that’s changing.

As drug development timelines shorten, analytical teams are under pressure to work faster, reduce manual tasks, and ensure tighter compliance with regulatory standards.

The desirable future is clear:

- Methods that are digitized, not described in prose

- Parameters that are standardized, not reinterpreted

- Systems that normalize and adjust methods automatically across platforms

- Data that is secure, traceable, and audit-ready

This vision isn't just about convenience—it’s about enabling faster delivery of therapies to patients.

3. The Pistoia Alliance: Building a Foundation for Digital Methods

Recognizing the widespread pain around method transfer, the Pistoia Alliance—a collaboration of pharma (GSK, Merck Sharp & Dohme LLC), technology vendors (ZONTAL, Agilent), and service providers (Astrix)—launched the Methods Hub initiative in 2020.

The goal of the project: evolve analytical methods from manual, text-based formats into fully digitized, machine-readable instructions. This digital shift enables method sharing, faster implementation, improves traceability, and significantly reduces human error.

The Methods Hub project helps address key industry needs:

- Create a common, standardized data format for method transfer using the Allotrope Framework technology

- Enable integration with any Chromatography Data System (CDS)

- Capture metadata and version control for compliance and audit trails

- Improve collaboration between internal teams and external partners by applying the FAIR principles

By standardizing how analytical methods are structured, stored, and exchanged, the initiative lays the groundwork for a more interoperable and automated analytical ecosystem.

4. From Theory to Practice: The Role of Digital Twins and Secure Repositories

Digital solutions are now turning this vision into reality. Tools like our digital platform allow scientists to create digital twins of analytical methods—machine-readable, structured representations that can be stored, searched, and reused securely.

Here’s what the end-to-end process with our platform looks like in action:

- A new HPLC method is created in the lab.

- It’s uploaded to the platform and converted into a digital twin.

- Scientists across the organization or external partners can search for the method.

- Once selected, the method is automatically normalized—adapting parameters to match the target instrument.

- The method is ready to run—no manual retyping or interpretation needed.

This approach eliminates manual conversions and cumbersome troubleshooting, improves reproducibility, and ensures that analytical methods remain consistent regardless of where, when, or how they are used.

5. Benefits for Pharma, CROs, CMOs, and CDMOs

Digitalizing analytical method transfer delivers significant value across the entire pharmaceutical value chain. For pharmaceutical companies, it means faster method transfer in R&D, manufacturing, or QC. By reducing variability in chromatography data, teams spend less time investigating discrepancies, allowing them to focus on innovation and production. It also enables greater flexibility to collaborate across multiple global sites and with external partners without the delays typically caused by incompatible systems or manual rework.

For CROs and CDMOs, digital method transfer simplifies the onboarding process for client protocols. Instead of navigating inconsistent formats or reconfiguring methods manually, these organizations can implement structured digital methods seamlessly into their existing platforms. This reduces the burden of validation and troubleshooting, while enabling them to serve clients with greater speed and reliability—strengthening long-term partnerships and client satisfaction.

Regulatory and quality assurance teams also benefit from this transformation. Digitized methods are inherently traceable and auditable, which increases confidence in data integrity and compliance readiness. Having a clear, version-controlled record of method changes simplifies regulatory submissions and inspections, reducing the risk of compliance issues and supporting a more robust quality management system.

6. The Future of Analytical Methodology Is Digital

Digitizing chromatographic methods is more than just a technical upgrade—it’s a fundamental shift in how analytical science is practiced and shared. By removing manual bottlenecks and enabling true interoperability between systems, it accelerates innovation and ensures that patients get access to safe, effective treatments faster.

For labs still relying on static documents, email chains, and handwritten notes—now is the time to modernize. The technology is ready. The standards are forming. And the benefits are too valuable to ignore.