Why Production Labs choose our LIMS

15 Ways It Simplifies Quality, Compliance, and Control

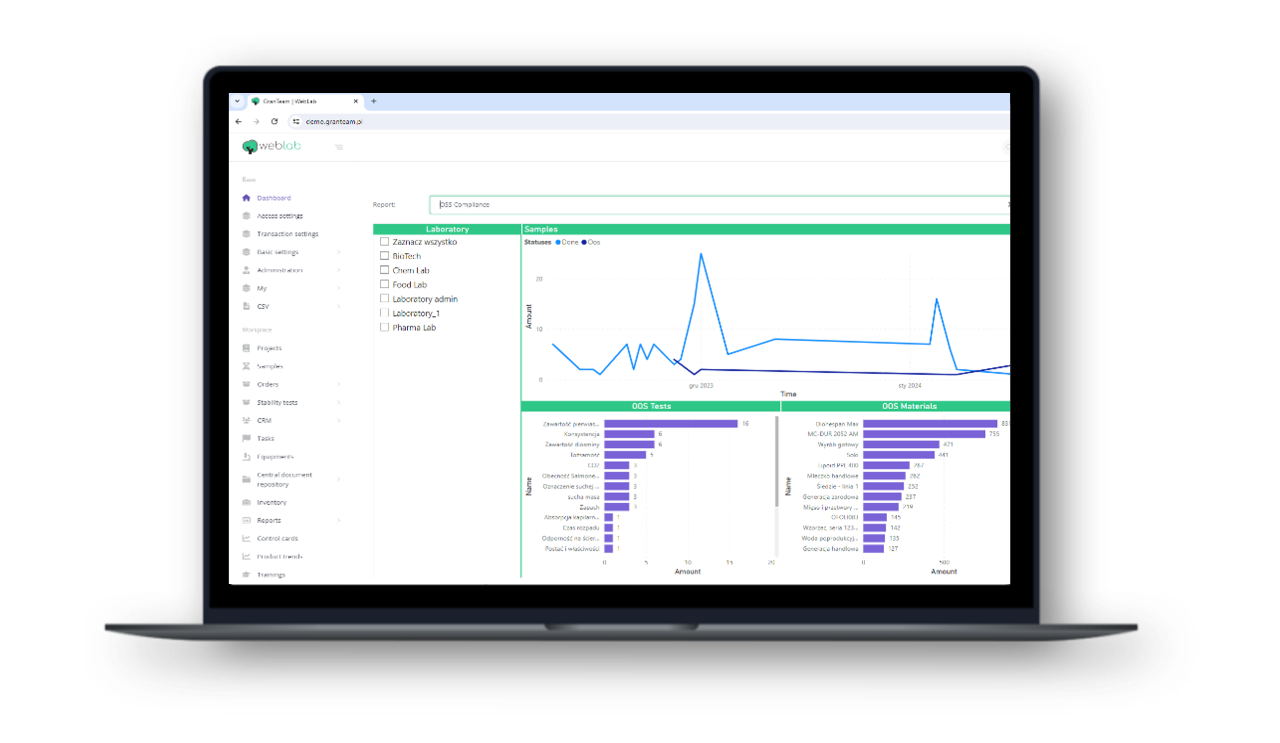

In production environments, every batch, every test, and every record matters. Whether you're manufacturing pharmaceuticals, chemicals, or food products, your lab needs to ensure consistency, traceability, and compliance without slowing down operations. That’s where our Laboratory Information Management System (LIMS), WebLab, comes in.

Here are 15 reasons why production labs choose WebLab to streamline their workflows and strengthen their quality systems.

1. Control Batch Quality from Start to Finish

Built-in statistical tools and control charts help you monitor batch performance in real time. You can detect deviations early, apply corrective actions, and ensure every batch meets your internal and regulatory standards.

2. Trace Every Batch with Confidence

Track the full lifecycle of each batch from raw material intake to final release. The system logs every transaction, test, and result, giving you a complete audit trail for internal reviews or external inspections.

3. Evaluate Test Results Across Specifications

Compare test results against multiple product specifications tailored to different customers, markets, or applications. WebLab helps users evaluate where a product meets requirements and determine its suitability for specific uses.

4. Plan Resources Without Guesswork

Coordinate equipment, personnel, and materials with built-in scheduling and inventory tools. You can align lab capacity with production demands and avoid bottlenecks.

5. Execute Standard Operating Procedures (SOPs) with Built-in Lab Execution Support (LES)

Define step-by-step workflows for each SOP, assign roles, and capture results directly in the system. This ensures consistency, reduces errors, and supports compliance with validated methods.

6. Embed Quality Assurance in Daily Operations

The Quality Assurance (QA) module includes alerts, control charts, and deviation tracking. It helps your team stay proactive about quality, not just reactive.

7. Spot Product Trends Before They Become Problems

Visualize trends across batches, time periods, or product lines. Use built-in statistical and analytics tools to identify shifts in performance, set up automatic notifications, and take action before issues escalate.

8. Generate PQRs Without the Manual Work

WebLab supports Product Quality Review (PQR) generation by aggregating test data, deviations, and trends. You can create comprehensive reports with minimal effort.

9. Centralize Documents with the SDMS Module

Store and manage all supporting documents—methods, certificates, reports—in a structured, searchable repository. Link them directly to samples, tests, or equipment.

10. Stay Aligned with GxP and 21 CRF Part 11 Requirements

Ensure data integrity, traceability, and user accountability with full support for electronic records and signatures. WebLab helps your lab stay audit-ready and fully compliant with global regulatory standards.

11. Keep Inventory in Check Automatically

Monitor reagent and material usage, set stock alerts, and track expiry dates. Inventory is linked to test methods, so consumption is calculated automatically.

12. Maintain Equipment Without Surprises

Schedule calibrations, maintenance, and validations. WebLab helps you prevent the use of out-of-spec equipment and keeps a full log of service history.

13. Train and Qualify Your Team with Confidence

Track training records, certifications, and competencies. Link qualifications to methods and equipment to ensure only authorized personnel perform critical tasks.

14. Validation-Ready with Expert Support

WebLab comes with complete validation documentation and processes. As your technology partner, we provide expert guidance during IQ/OQ/PQ processes to ensure seamless validation, data integrity, and regulatory compliance from day one.

15. Maintain ISO/IEC 17025 Compliance in Daily Lab Operations

Strengthen consistency, traceability, and data reliability with controlled access, validated methods, and structured documentation across testing and calibration workflows.